The equipment used in dairy

Automatic milking systems

Automatic milking systems (AMS) enable dairy farmers to address two key challenges:

- Availability of labour

- Lifestyle associated with dairying

Much of the Australian dairy industry is pasture-based. Any AMS system must rely on voluntary movement of cows to and from the paddocks, and be able to handle large herds. Current research is examining the constraints to successful implementn of AMS into the Australian dairy industry

Single box AMS units

Automatic milking systems have been used commercially overseas for many years. In Europe, over half of new milking machine installations involve automation. These AMS are single box units with the capacity to milk about 70 cows each. Only a small number of dairy farmers in Australia have implemented the AMS single box unit on their dairy farms.

AMS Research program

The traditional AMS are single boxes developed for the European market which has small herds that are often housed indoors. The Future Dairy project, funded in part by Dairy Australia, has proven that single boxes can operate effectively under Australia’s pasture-based systems, achieving both high pasture utilisation and acceptable AMS unit utilisation. The “Management Guidelines for Pasture-based AMS farms” publication can assist you greatly if you choose the AMS path. More information on the R&D program to facilitate voluntary movement of cows through AMS is shown on the video here below.

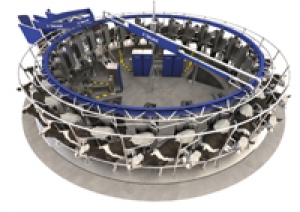

Robotic Rotary

Further research in the Future Dairy project has led to the development of a robotic rotary dairy capable of milking at least 300 cows. The prototype was launched in November 2010 and is likely to be commercially available to Australian dairy farms in 2012.

View the video demonstration of the robotic rotary.